Lasers and robotics are both used by manufacturers for their speed and precision. It’s natural that these two technologies frequently work hand in hand in production lines to perform laser welding.

Emerging applications like EV batteries demand more speed than ever. To meet this need, laser heads cannot be mounted on robotic arms like they usually are.

Higher speed can be achieved by performing laser welding remotely and using robots to clamp every single weld at very high speed. This is what we call robot-assisted laser welding.

Remote Laser Welding Assisted by Robots

While traditional laser welding makes use of a six-axis robot to move the laser welding head and follow the weld seam, robot-assisted laser welding uses a process called remote laser welding.

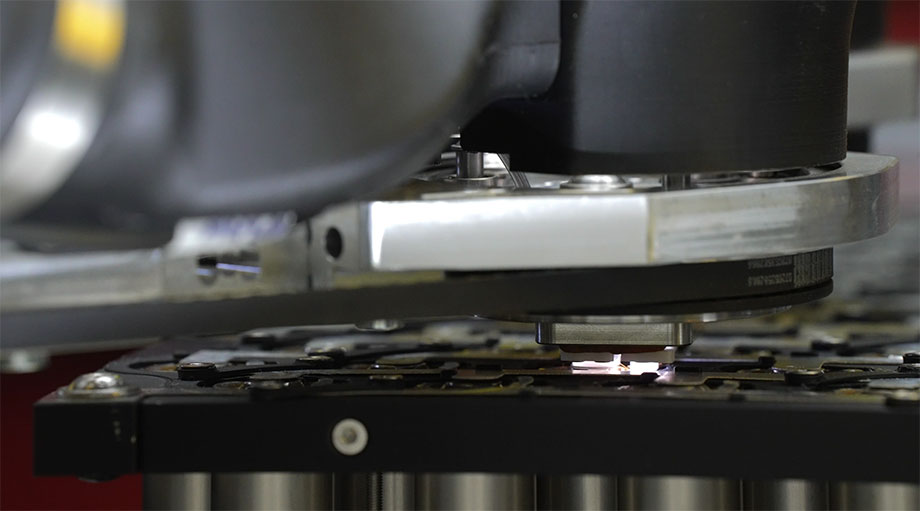

Remote laser welding uses optical components to direct the laser beam from a distance. Fast-rotating mirrors called galvanometers move the laser beam with high precision and speed to allow precise weld patterns.

Remote laser welding involves few mechanical movements because the laser head has a large field of view and rarely needs to be moved. For example, when welding cylindrical cells, it takes less than 1 microsecond (1 millionth of a second) to move the laser beam from one battery cell to the next.

The increased speed offered by remote laser welding is critical when welding small and sensitive components like battery tabs.

Watch the following videos to compare robotic laser welding with robot-assisted remote laser welding. In the first one, you’ll see robotic laser welding inside a welding cell and, in the second one, battery laser welding for the automotive industry.

Robotic Laser Welding (Operated by KUKA Robots)

Robot-Assisted Laser Welding (Assisted by SCARA Robots)

How Can Robots Assist During Remote Laser Welding?

Clamping can be difficult to adapt to part variations, but it is necessary to achieve high-quality and consistent welds. Robots make this easy by offering the possibility to dynamically adjust clamping tools for each part.

During remote laser welding, industrial robots like SCARA robots can assist the laser welding process, as shown in the previous video. Working in 4 axes, these clamping robots offer more versatility in three ways:

- When vision systems detect localized deviations, robots can make automatic adjustments to the clamping, making the laser welding process more accurate and reliable.

- If various part models need to be welded, different welding sequences can be programmed, each taking into account different clamping positions.

- If part designs are changed, the laser welding sequence is easy to update without having to design a new clamping system.

Robot-Assisted Laser Welding Machine

|

Laserax has developed a fiber laser welding machine specifically designed to weld battery modules and cells at a high pace and with a high yield. This machine was developed to address the challenges specific to battery welding. It includes features such as:

|

|

Develop Your Product with Us

If you’re interested in battery laser welding assisted by robots, contact us today. We can accompany you through design, prototyping, preproduction, and full-scale production.