When working with lasers, it's essential to understand the concept of laser power. Laser power is one of the most important parameters to consider when choosing a laser, as it plays a key role in determining the effectiveness of laser processes.

In laser material processing for example, laser power directly impacts the speed of processes like laser welding, laser cleaning, laser texturing, laser cutting, and laser marking. Power is expressed in many ways, and it can become confusing.

Let’s go over everything you need to know about laser power.

- What is Laser Power?

- Continuous vs. Pulsed Laser Powers

- Laser Parameters that Control How Laser Power is Used

- Average Power, Peak Power, and Power Density: What’s the Difference?

- Examples of Laser Powers

What is Laser Power?

The NIH defines laser power as “the rate at which energy is emitted from a laser”. In simpler terms, it’s a measure of how quickly a laser releases energy.

Laser power is expressed in watts (W), kilowatts (kW), or milliwatts (mW). Each watt indicates that the laser can emit 1 joule of energy per second. This means that a 100W laser can emit 100 joules of energy per second.

Laser power must not be confused with power density. A 50W and a 200W laser can focus energy the same way and perform the same tasks. Since higher power lasers emit more energy in one second, they can simply perform the same work faster.

In the following definition by Xometry, they introduce the idea that laser power is related to how energy is dispersed over an area (energy concentration).

“Laser power is the energy delivered by a laser beam per unit of time

and per unit of area.”

This is incorrect. Laser power is only about how much energy can be emitted during one second. That’s it.

Continuous vs. Pulsed Laser Powers

The two main types of lasers use their available laser power differently.

- Continuous lasers release a consistent level of energy over time. For example, a 50W continuous laser consistently releases 50 joules of energy per second.

- Pulsed lasers release energy in pulses, with brief pauses between each release of energy to accumulate energy before the next pulse is emitted. This allows pulsed lasers to reach higher energy peaks.

Pulsed lasers are often preferred over continuous wave lasers because they can generate the high energy peaks required for material ablation, which is needed for processes like laser marking, laser cleaning, and laser texturing.

Laser Parameters that Control How Laser Power is Used

Laser parameters can be modified to control how the available laser power is used. Let’s go over common laser parameters to understand how they can help achieve different results.

Pulse Energy

Each pulse contains a specific amount of energy. At Laserax, our lasers are typically configured to release 1 millijoule (mJ) of energy per pulse. We sometimes lower the pulse energy for applications that require less energy. For example, laser annealing stainless steel requires a slow heating of the surface, so lower energy peaks are needed.

Pulse Duration

Each laser pulse has a specific duration, allowing to concentrate the energy within a short lapse of time. The shorter the pulse duration, the higher the peak power. This is also known as the pulse length.

Femtosecond lasers, for example, get their name from their pulse duration, which ranges between a few femtoseconds to hundreds of femtoseconds. At Laserax, our lasers are configured with pulse durations that range from 20 nanoseconds to 500 nanoseconds.

Pulse Repetition Rate

The pulse repetition rate is the number of pulses per second. It is often expressed in hertz (Hz) or kilohertz (kHz), where 100 kHz is 100,000 pulses per second.

| Pulses Per Second | Hz | kHz |

|---|---|---|

| 100,000 | 100,000 | 100 |

Higher power lasers can be used to release more pulses per second. For example, a 100W laser can release 100,000 pulses of 1 mJ per second, whereas a 500W laser can release 500,000 pulses of 1 mJ per second.

To further clarify this concept, a 100W can also release 500,000 pulses per second, but to do this, the pulse energy needs to be lowered to 0.2 mJ. This is because the repetition rate controls how laser power is distributed over time. If you multiply the pulse energy with the pulse repetition rate, you obtain the laser power.

| Laser Power | Pulse Energy | Pulse Repetition Rate |

|---|---|---|

| 100W | 1 mJ | 100 kHz |

| 100W | 0.2 mJ | 500 kHz |

| 500W | 1 mJ | 500 kHz |

To meet the needs of a high repetition rate (i.e., produce more pulses per second), a high-quality laser scanning head is needed to redirect the laser beam more efficiently.

Spot Size

Laser beams can have different shapes (round, square, rectangle, etc.) and the laser energy can be distributed unevenly over that area. The spot size represents the diameter of the laser beam where energy is the most focussed. For Gaussian beams, it stops where the laser beam's intensity drops to ~13.5% of its peak value.

A smaller spot size means a higher energy peak. It can be adjusted with optical components like focal lenses and beam expanders.

Some laser processes require a smaller spot size. For example, we typically use a 0.125 mm spot size for laser marking. But for processes that require going deeper into the material, we use a smaller spot size of 0.075 mm.

Beam Profile

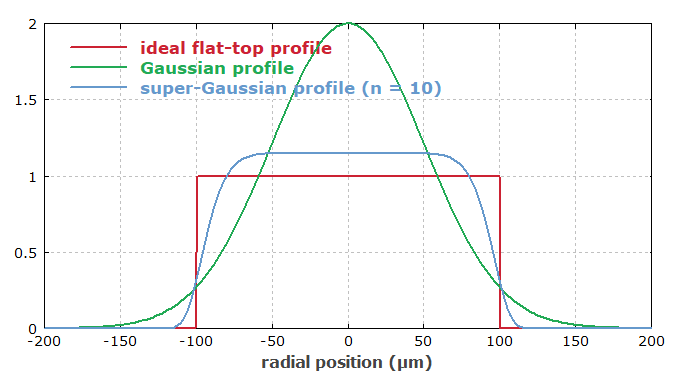

Image courtesy of RP Photonics

A beam profile is how the energy of the laser light is distributed along the diameter of the laser beam. It is measured using a beam profiler, which provides a graphical representation as shown in the preceding image. You can measure it at different locations along the laser beam path.

If you look at the Gaussian profile in the preceding image, the further you are from the center of the beam, the lower the energy level. If you look at the flat-top profile, the energy level is constant. Gaussian profiles can reach higher peak powers and smaller spot sizes, whereas flat top profiles make a better use of the total energy and can achieve more accurate results (like cleaner cuts when laser cutting).

Flat top beams are less cost efficient than Gaussian beams because they require additional setup (i.e., diffractive optical elements that modify the beam’s shape). Gaussian beams have a “natural” beam shape.

Average Power, Peak Power, and Power Density: What’s the Difference?

Let’s break down important concepts to understand the beam power levels achieved with lasers. As you will see, a 100W laser can generate power values well beyond 100W.

Average Power

The average power is the same thing as the laser power. It represents the average output power of the laser over one second. A 100W laser, whether it is continuous or pulsed, has an average power of 100W.

Peak Power

The peak power is the highest power output achieved by the laser during a specific time interval. In simpler terms, it indicates the amount of energy a pulse contains with respect to its duration.

When millijoules are concentrated within a small timeframe, they reach high energy levels. The effect is similar to when you almost completely block the nozzle of a hose. The resulting water pressure coming out of the small hole is much greater. The same applies to the energy of the laser beam when it is focussed in a small area and a small duration.

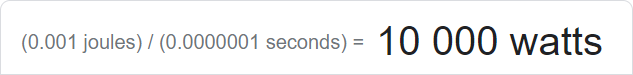

Peak Power Calculation

To calculate the peak power, simply divide the pulse energy (in joules) by the pulse duration (in seconds). For example, 1 mJ pulse with a pulse duration of 100 ns has a peak power of at least 10,000 watts.

Power Density

Power density, also known as irradiance, is a parameter that helps us understand the concentration of energy. Measured in W/cm2, it shows what the rate of energy transfer (expressed in watts) is in relation to the beam size (expressed in cm2).

To determine the power density, you can divide the laser power by the beam size. For example, our 100W lasers with a beam size of 0.000,067,929,1 cm2 generate a power density of ~1,470,000 W/cm2.

Examples of Laser Powers

High-Power Laser Engraving

This 500W fiber laser system digs deep into the material to create shotblast resistant markings. The laser power used for this is high compared to most laser marking applications, as higher energy levels are required to dig efficiently into the metal.

Low-Power Laser Annealing

This low-power fiber laser system is configured to slowly heat the stainless steel surface to create a chemical reaction under the surface, allowing internal oxidation to occur while keeping the protective passivated layer intact on the surface.

Powering Industrial Laser Applications

Mastering how laser power is used is essential to optimize laser processes. If you are interested in exploring the potential of laser marking, cleaning, texturing, or welding for an industrial application, contact a Laserax expert. We can provide complete laser solutions and develop a laser process for you.